Understanding GMAW transfer modes - The Fabricator

Dec 14, 2008 · The gas metal arc welding (GMAW) process uses four basic modes to transfer metal from the electrode to the workpiece. Each mode of transfer depends on the welding process, the welding power supply, and the consumable, and each has its own distinct characteristics and applications.

Sheet metal bending calculation basics - The Fabricator

Nov 9, 2012 · The second flat-blank-development example adds the two dimensions (from edge to the apex), and subtracts a bend deduction. In this case, the calculations use a complementary angle for the OSSB, and the dimensions are called from the edge to the apex—again, as specified in Figure 4.. Outside Setback (OSSB)

Bending Basics: The fundamentals of how to bend metal

Jan 2, 2014 · While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more.

Gas tungsten arc welding fundamentals: Understanding GTAW

Feb 19, 2001 · 2. Thoriated tungstenis the most common type of tungsten electrode for use on carbon and stainless steel.It can be purchased with 1 or 2 percent thorium. The thoriated tungsten starts readily and maintains a stable arc. It has a greater resistance to contamination and will maintain a sharp point and will not break down as readily as pure tungsten.

Stamping 101: Anatomy of a Mechanical Stamping Press - The …

Jan 15, 2008 · Figure 1. In a nongeared drive, the flywheel, clutch, and brake are located on the eccentric or crankshaft. As a rule of thumb, full press energy is available between half of the top press speed and the top press speed.

Die Basics 101: Intro to stamping - The Fabricator

Apr 11, 2005 · Blanking—A dual-purpose cutting operation usually performed on a larger scale, blanking is used in operations in which the slug is saved for further pressworking.It also is used to cut finished piece parts free from the sheet metal. The profiled sheet metal slug removed from the sheet by this process is called the blank, or starting piece of sheet metal that will be cut or …

Tube bending basics: How to bend tubing and metal pipe - The …

Feb 24, 2014 · The pressure die (also called a pressure slide) supports the outside radius during bending. The pressure die can be stationary; it can follow the workpiece, sliding on rollers at the same rate the workpiece is being drawn into the bend; or it can be “boosted,” pushed with hydraulics or (more common today) electrical servomotors, further minimizing wall thinning.

Metal Grades: Designations for grading sheet metals - The Fabricator

Sep 12, 2016 · Martensitic stainless steels (also part of the 4XX series) have more carbon than the ferritic grades. They are capable of being heat-treated to a variety of useful hardness and strength levels. However, they are not as corrosion-resistant as austenitic or ferritic grades.

Grain direction’s effect on sheet metal bending - The Fabricator

Mar 24, 2022 · Question: A previous article of yours suggests that forming “with” the grain direction will manifest cracks. I might be confused over the verbiage. Does this mean the grain runs perpendicular or parallel to the bend line? I was researching the topic because we are bending 0.060-in.-thick 3003 H14 aluminum (see Figure 1), and my toolmaker wants me to …

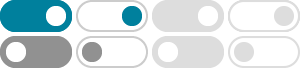

Guidelines for tungsten electrode and color types - The Fabricator

Mar 7, 2006 · Editor's note: To read an update regarding tungsten electrodes guidelines, click here. Tungsten is a rare metallic element used for manufacturing gas tungsten arc welding (GTAW) electrodes. The GTAW process relies on tungsten's hardness and high-temperature resistance to carry the welding current to the arc. Tungsten has the highest melting point of …